GK Serie

Minimum space, maximum capacity.

GK series heat exchangers meet the expectations of the ever-increasing demand for environmentally friendly, energy efficient cooling and heating systems. The new plate design of this heat exchanger generates higher turbulence in the channels, improves heat transfer and increases the efficiency. This heat exchanger is therefore ideal when a limited amount of space is available and maximum capacity is required.

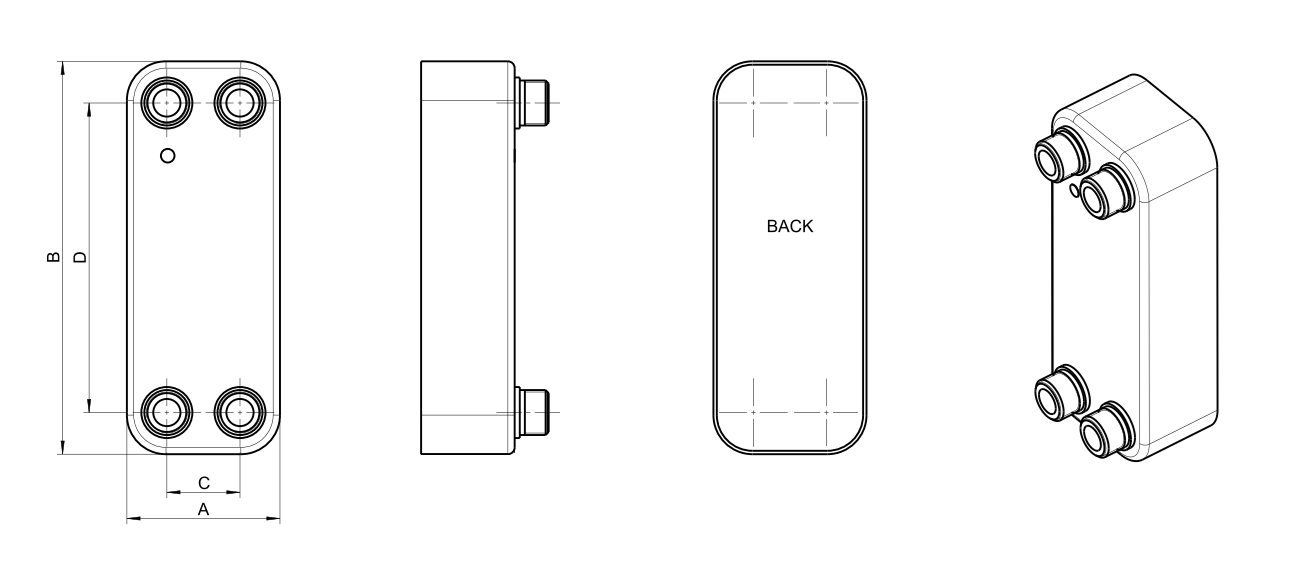

Dimensions

| Type | Standard dimensions (mm) | ||||

|---|---|---|---|---|---|

| Plate heat exchanger | A | B | C | D | Max. number of plates |

| GK… 108H | 74 | 204 | 40 | 170 | 50 |

| GK… 228H | 90 | 328 | 43 | 279 | 50 |

| GK… 550M/H | 124 | 532 | 73 | 478 | 100 |

| GK… 770M/H | 278 | 539 | 200 | 436 | 200 |

| Also available as an advanced evaporator with a special “Delta InjectionTM“ distribution system for the refrigerant inlet. | |||||

| GK… 550H-AE | 124 | 532 | 73 | 478 | 100 |

| GK… 770H-AE | 278 | 539 | 200 | 460 | 200 |

Applications

Heat exchangers from the GK series are used for, among other things

District heating

Heat pumps

Heat recovery

Hot water

Features

- Plate material: Stainless steel (AISI316/1.4404)

- Brazing material: Copper

- Design temperature: -196°C to +200°C

- Design pressure: Up to 50 bar

- Third party approval: PED (CE), ASME VIII-1 – other certificates on request

Can we help you?

If you are looking to talk to experts that know the installation sector and industry and everything else there is to know about heat transfer, we are standing by to help. Call us or send us an e-mail!