GNS Serie

The nickel-brazed alternative

A nickel brazed heat exchanger offers practically all the advantages of a standard copper brazed heat exchanger, but because of its nickel connection, it can be used in applications where corrosive media are used. Therefore, this heat exchanger is often used in ammonia systems, demi-water applications and other applications with corrosive liquids.

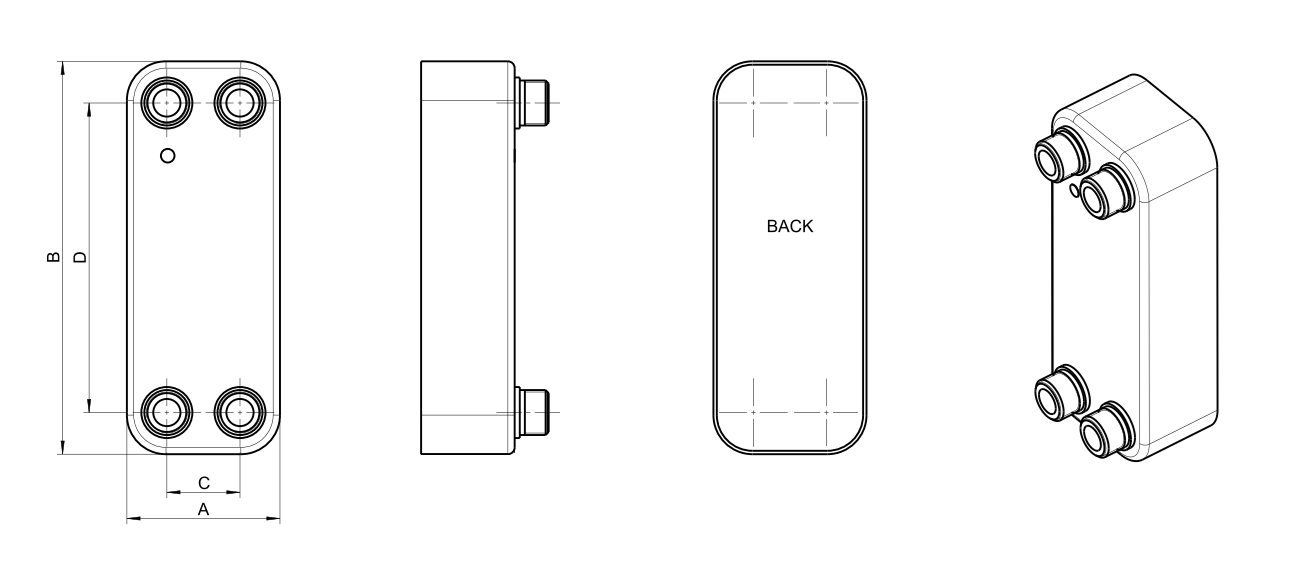

Dimensions

| Type | Standard dimensions (mm) | ||||

|---|---|---|---|---|---|

| Plate heat exchanger | A | B | C | D | Max. number of plates |

| GNS 100M | 74 | 204 | 40 | 170 | 50 |

| GNS 200H | 90 | 231 | 43 | 182 | 50 |

| GNS 220H | 90 | 328 | 43 | 278 | 50 |

| GNS 240H | 90 | 464 | 43 | 415 | 50 |

| GNS 300H | 124 | 173 | 73 | 120 | 50 |

| GNS 400H | 124 | 335 | 73 | 281 | 100 |

| GNS 500H | 124 | 532 | 73 | 478 | 100 |

| GNS 700L/M | 271 | 532 | 200 | 460 | 150 |

| GNS 800H | 271 | 532 | 161 | 421 | 150 |

| Also available as an advanced evaporator with a special “Delta InjectionTM“ distribution system for the refrigerant inlet. | |||||

| GNS 400H-AE | 124 | 335 | 73 | 281 | 100 |

| GNS 500H-AE | 124 | 532 | 73 | 478 | 100 |

| GNS 700M-AE | 271 | 532 | 200 | 460 | 150 |

| GNS 800H-AE | 271 | 532 | 161 | 421 | 150 |

Applications

Heat exchangers from the GNS series are used for, among other things:

Ammonia applications

Corrosive media

Industrial applications

Laser cooling

Features

- Plate material: Stainless steel (AISI316/1.4404)

- Brazing material: Nickel

- Design temperature: -196°C to +200°C

- Design pressure: Up to 16 bar

- Third party approval: PED (CE), ASME VIII-1 – other certificates on request

How can we help you?

Would you like to talk to people who know the installation sector and industry and who know everything about heat transfer? We are happy to help you. Call or email us!