XCR Serie

Extra corrosion resistant heat exchanger for swimming pool applications

Chlorine, essential for pool hygiene, often damages pool equipment. XCR series heat exchangers are equipped with SMO 254 plates and are resistant to corrosion, even with the high chlorine levels common in swimming pools. The special plate design and the enlarged, stronger solder joints (copper or nickel) make the entire heat exchanger more stable and resistant to high pressures.

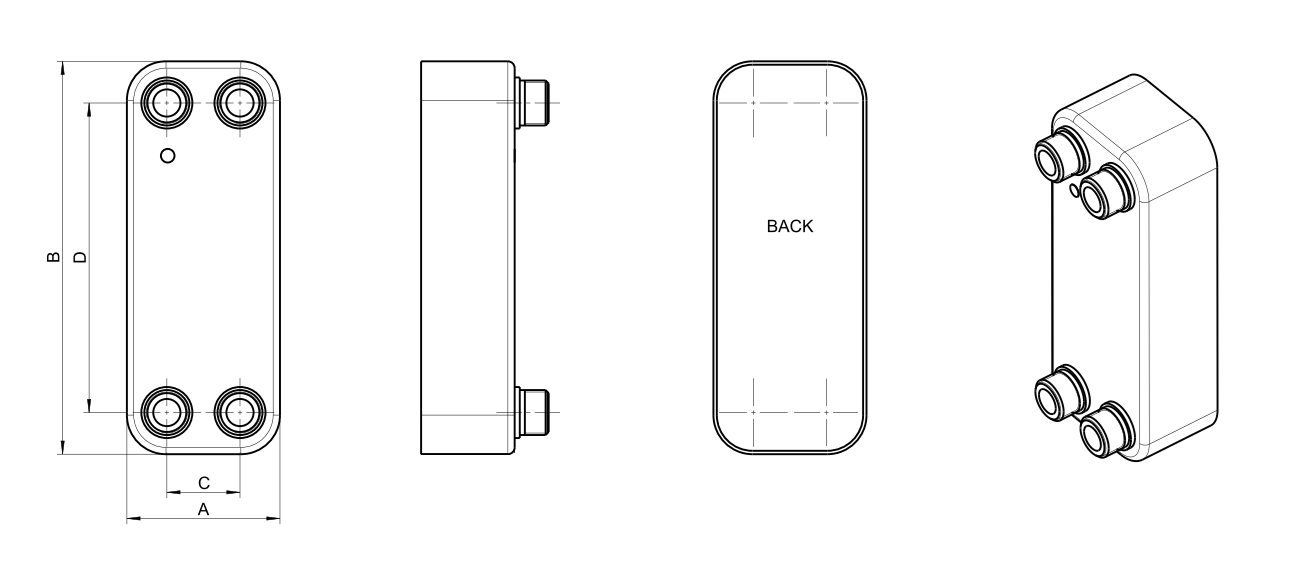

Dimensions

| Type | Standard dimensions (mm) | ||||

|---|---|---|---|---|---|

| Plate heat exchanger | A | B | C | D | Max. number of plates |

| GBS 220H-XCR | 90 | 328 | 43 | 279 | 50 |

| GBS 240H-XCR | 90 | 464 | 43 | 415 | 50 |

| GBS 400H-XCR | 124 | 335 | 73 | 281 | 100 |

| GNS 220H-XCR | 90 | 464 | 43 | 415 | 50 |

| GNS 240H-XCR | 90 | 464 | 43 | 415 | 50 |

| GNS 400H-XCR | 124 | 335 | 73 | 281 | 100 |

| GNS 500H-XCR | 124 | 532 | 73 | 460 | 100 |

| GNS 700L/M-XCR | 271 | 532 | 200 | 460 | 150 |

Applications

Heat exchangers from the XCR series are used for, among other things:

Features

- Plate material: Stainless steel SMO 254 (1.4547)

- Brazing material: Copper/Nickel

- Design temperature: -196°C to +200°C

- Design pressure: Copper brazed up to 31 bar / nickel brazed up to 16 bar

- Third party approval: PED (CE), ASME – other certificates on request

Can we help you?

If you are looking to talk to experts that know the installation sector and industry and everything else there is to know about heat transfer, we are standing by to help. Call us or send us an e-mail!